N2 Blanketing System NK-NB2L

INTRODUCTION

The MODEL NK-NB2L series blanket gas valves ensure that a constant gas pressure is maintained in the vapor space of storage tank. When liquid is removed from a tank or the temperature is reduced, a vacuum would be developed.With the blanket gas regulator, a blanket gas is supplied to prevent any vacuum from developing and to maintain the desired blanket pressure.

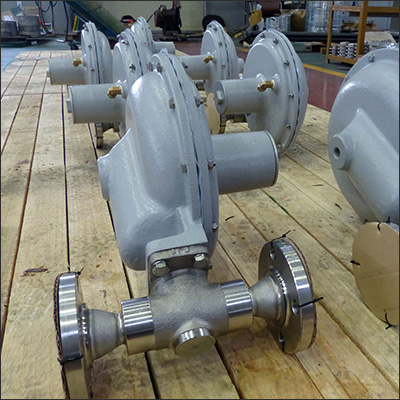

MODEL NAME : NK-NB2L

NK-NB2L PHOTO

NK-NB2L PHOTO

DESIGN AND FUNCTION

|

SIZE |

INLET MAX PRESSURE | SETTING PRESSURE |

MAX FLOW |

|

1″ / 2″ |

10kgf/cm2 | 20~500mmH2O |

26,700SCFH |

The NEOTECHKOREA Nitrogen Gas Blanketing Valves ensure that a constant gas pressure is maintained in the vapor space of storage tank. When liquid is removed from a tank or the temperature is reduced, a vacuum would be developed. With the blanket gas regulator, a blanket gas is supplied to prevent any vacuum from developing and to maintain the desired blanket pressure. The Model WNBSL is a pilot-controlled stainless steel valve using a single oversized diaphragm actuator. The Model NK-NB2L is a direct–operated stainless steel valve using a single oversized diaphragm actuator. The oversized actuator offers high sensitivity to change in tank pressure, which increases the accuracy. The valves are fully balanced under all operating conditions, allowing for operation with varying inlet pressures. Blanketing pressure set point is easily controlled by a single adjusting screw.

MATERIALS

| PART NAME | MATERIALS STANDARD | MATERIALS OPTIONAL |

| BODY | SUS304 / SUS316 | SUS316 L |

| ORIFICE | SUS304 / SUS316 | SUS316L |

| CONTROL SPRING | SUS304 / SUS316 | SUS316L |

| DIAPHRAGM | Teflon(Diaphragm seal) | Teflon(Diaphragm seal) |

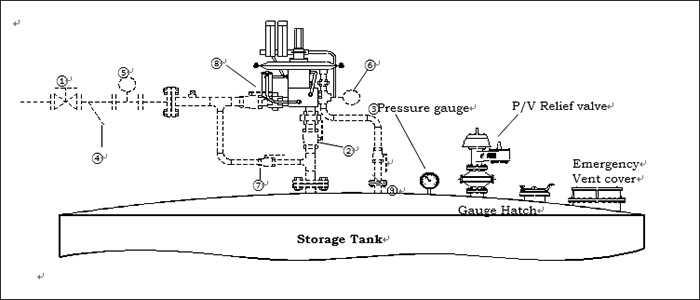

INSTALLATION

The corporation win blanketing valve has been assembled, calibrated and tested. The only adjustable feature is the gas blanketing set point. It has been adjusted to the pressure indicated on the purchase order at the specified supply pressure and set point.

(1) N2 Supply Main line;

It must be removed dirt and pipe scale.

The Mainline should be installed with a 65-mesh strainer to remove dirt and pipe scale.

(2) Sensing Line;

It must be drained (slope down) and not contain low points or traps that could contain liquid. The sensing line should be 1/2” tubing or pipe.

MAINTENANCE

In Every month;

1. Open the drain port on the main supply line strainer (④) and filter of strainer must be cleaned.

2. Check the unit for problems, loose connection, etc.

3. Check the inlet main pressure (⑤) and to be compared with stamped pressure range on the valve name plate

4. Check the blanketing pressure (⑥)