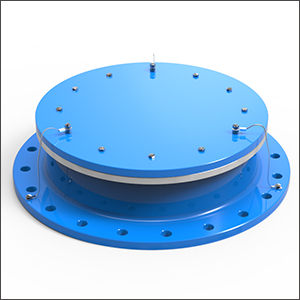

Emergency Pressure / Vacuum Vent Cover

NK-EV30W

MODEL NAME : NK-EV30W

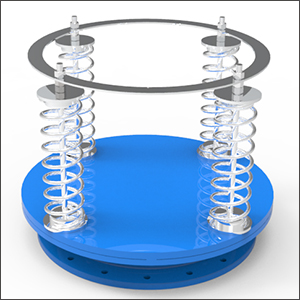

NK-EV30S

MODEL NAME : NK-EV30S

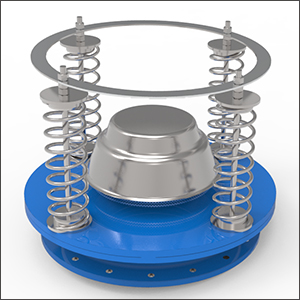

NK-EV31W

MODEL NAME : NK-EV31W

HOVER ME

MODEL NAME : NK-EV31S

EMERGENCY PRESSURE/VACUUM VENT COVER

Emergency vent cover is required by API on storage tanks in order to protect the tank against excessive pressure caused by external fire exposure or flashes within the tank.The excessive pressure caused by an external fire is generally because an adjacent tank is on fire or some other structure in close proximity is on fire. Flashes are generally caused by a chemical reaction in the tank.

Regardless of the cause of the excessive pressure, an opening larger than the normal pressure/vacuum valve is necessary in order to carry off the additional volume resulting from the fire exposure the tank is experiencing.

API 2000 states emergency venting may be accomplished by the use of:

1. Larger or additional open vents.

2. Larger or additional pressure/vacuum valves or pressure relief valves.

3. A gage hatch which permits the cover to lift under abnormal internal pressure.

4. A manhole cover which permits the cover to lift under abnormal internal pressure.

5. A connection between the roof and shell which is weaker than the weaker vertical joint in the shell or l shell to bottom connection (weak roof to shell weld).

Emergency vent cover is used on liquid storage tanks and other process vessels or systems to prevent structural damage due to excess internal pressure caused by fire or etc. Usually, storage tanks are pressurized when liquid is pumped in, compressing the existing vapor or when rising temperatures cause increased evaporation or expansion of existing vapor.

To prevent tank damage, vapor must be allowed out of the tank at specified pressure conditions. The volume rate of venting depends upon the tank size, volatility of the tank contents, the pumping rates and the temperature.

EMERGENCY PRESSURE/VACUUM VENT COVER OPERATION

When excessive pressure builds within the storage tank the model WE30 Emergency Pressure Relief Vent hinged cover begins to open at the predetermined set pressure, relieving excess s pres sure. When the overpressure has dissipated the cover reseats onto the base. The hinge mechanism prevents misalignment and provides an accurate reseat.

When excessive vacuum builds within the storage tank the spring loaded pallet lifts, breaking the seal between the seat and pallet, allowing vapors to pass through the valve orifice and relieving the vacuum buildup. The vacuum valve reseals upon relief and remains sealed.