Pressure Vacuum Relief Valve

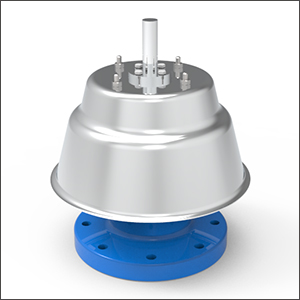

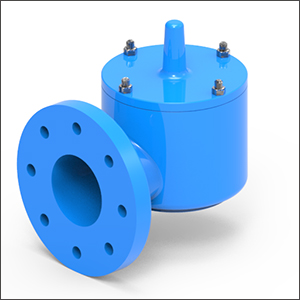

NK-BV10 Series

MODEL NAME : NK-BV10 SERIES

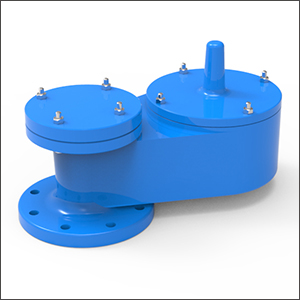

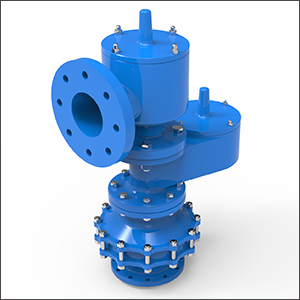

NK-BV11 Series

MODEL NAME : NK-BV11 SERIES

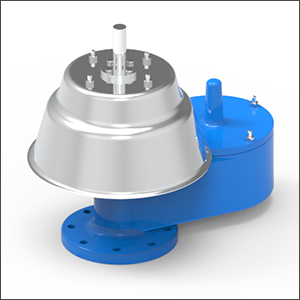

NK-BV12 Series

MODEL NAME : NK-BV12 SERIES

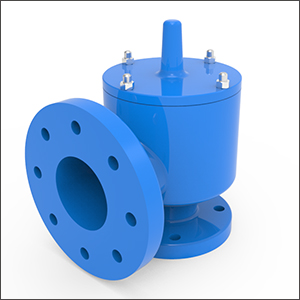

NK-BV13 Series

MODEL NAME : NK-BV13 SERIES

NK-BV14 Series

MODEL NAME : NK-BV14 Series

NK-BV15 Series

MODEL NAME : NK-BV15 Series

NK-BVF60 Series

MODEL NAME : NK-BVF60 Series

NK-BVF70 Series

MODEL NAME : NK-BVF70 Series

PRESSURE/VACUUM VALVES SAVE MONEY

Actually, any properly sized opening in the tank’s upper structure protects the tank from damage, but utilizing a pressure and vacuum valve also serves to accomplish other advantages. Two of the more important are: economic savings and fire hazard protection. In 1952, American petroleum Institute developed a formula to determine tank evaporative losses. The API equation was formulated after the results of a total of 256 individual tests were compiled.

Of the 256 tanks tested (½ with open vents and ½ with pressure/vacuum valves), only 178 were considered valid. The remainder was eliminated because of inadequate data, obviously incorrect test methods, poor tank conditions, or leaky fittings. The API has a formula for calculating tank breathing loss. The principle factors are turnovers per year, true vapor pressure of the product, diameter of the tank in feet, the average daily ambient temperature change, and the paint factor.

The test was conducted on tanks containing gas-line with pressure and vacuum valves set at oz. pressure and ½ oz. vacuum. API2521 states that ½oz. is the usual setting.

REDUCED CORROSION

An additional reason for using pressure/vacuum valves, they help reduce overall corrosion in the plant. Plant corrosion is reduced due to less product escaping from the tank and therefore less corrosion is produced by escaping vapors. This means overall plant maintenance is reduced thereby saving labor and dollars.

RECOMMENDED AND REQUIRED

Pressure/vacuum valves are recommended by API 2000 for use atmospheric storage tank in which oil with a flash point below 100℉ is stored. OSHA states that tanks storing Class 1 liquids shall be equipped with venting devices which shall be normally closed except under pressure or vacuum condition. Generally speaking, the majority of the regulatory bodies dealing with tank safety, API, OSHA, NFPA, Insurance Companies etc. require installation of these devices on flammable liquid storage tanks.

SIZING A PRESSURE/VACUUM RELIEF VALVE

API standards are provided as an engineering aid for specification and selection of “normal” and “emergency” pressure and vacuum relief valves for aboveground liquid petroleum storage tanks. Normal venting capacity is obtained without exceeding pressure or vacuum that would cause physical damage or permanent deformation to the tank. The following will help in sizing a pressure/vacuum valve:

1. NORMAL RELIEF : the sum of vapor replacement resulting from emptying or filling and thermal in-breathing or out-breathing.

2. EMERGENCY RELIEF : thermal out-breathing from fire exposure.

3. ALL TANKS : generally require the sizing of a normal pressure and vacuum relief valve to be sized and an independent emergency relief valve to be sized separately.

4. FLOW CURVES : these curves provide pressure and vacuum capacity which is required for sizing.