Air Release Valve NK-AR17E

DESIGN AND FUNCTION

The Float ball type AIR RELEASE & VACUUM BREAKER, model NK-AR17, wasdesigned, manufactured and tested for allowing atmospheric air through the valve to rapidly displace draining liquid in the pipeline and prevent internal negative pressure damaging the arrangements potentially. To prevent damage, vapor must be allowed into or out of the pipeline & at specified vacuum condition. The volume rate of venting depends upon the pipe size, the pumping rates and the temperature. Refer to API Standard 2000 for the procedures to determine venting requirements.

MODEL NAME : NK-AR17E

NK-AR17E PHOTO

NK-AR17E PHOTO

SPECIFICATIONS

| MODEL NAME | NK-AR17E |

| TYPE | END-LINE TYPE |

| SIZE | 1” THROUGH 12” |

MATERIALS

| PART NAME | MATERIALS STANDARD | MATERIALS OPTIONAL |

| BODY | Carbon Steel, Stainless steel | Super duplex |

| FLOAT DISC | All Material +PP | All Material +PP |

| HOOD | 304 S.S,316 S.S,316L S.S | Hastelloy, Alloy 20, Monel, Inconel |

| GASKET | 304 SS / 316SS | 316L SS |

| BOLT and NUT | 304 SS / 316SS | 316L SS |

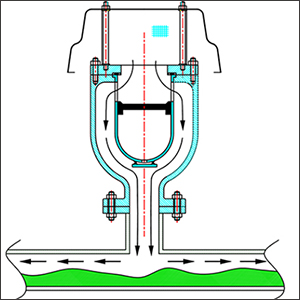

NK-AR17E VALVE OPEN

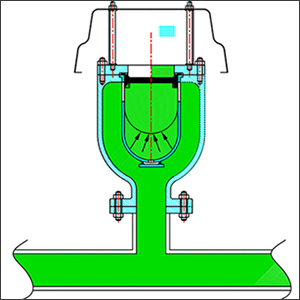

NK-AR17E VALVE CLOSE

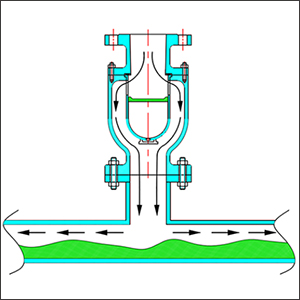

NK-AR17I VALVE OPEN

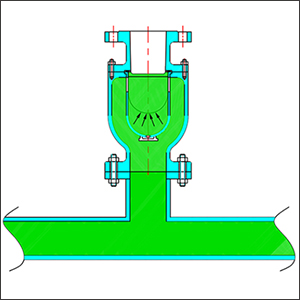

NK-AR17I VALVE CLOSE

The Float ball type AIR RELEASE & VACCUM BREAKER was designed,manufactured and tested for allowing atmospheric air through the valve to rapidly displace draining liquid in the pipeline and prevent internal negative pressure damaging the arrangements potentially. To prevent damage, vapor must be allowed into or out of the pipeline & at specified vacuum condition. The volume rate of venting depends upon the pipe size, the pumping rates and the temperature. Refer to API Standard 2000 for the procedures to determine venting requirements. During filling, air that occupies the empty pipe must be evacuated ahead of the incoming liquid in a controlled and efficient manner so that surge and water hammer are minimized and liquid completely fills the pipe. During draining, whether planned or unexpected, air must be admitted into the system to replace the out fiowing liquid to avoid excessive vacuum and possible pipeline damage. Air release valve are designed to release accumulated air pockets from the system, while pressured pipelines. Air pockets increase energy consumption because pumping operation will be at higher water heads to overcome pressured air. Air release valves are have function to protect high shock and surge pressure, water hammer and liquid overfiow from fresh or sea water pipelines.