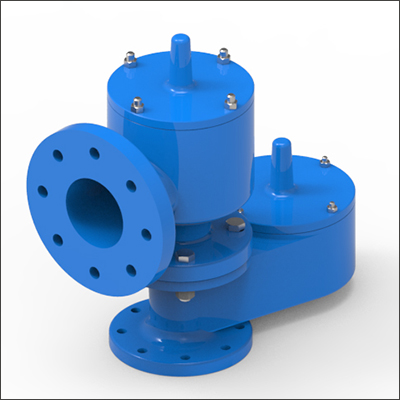

Pressure Vacuum Relief Valve NK-BV15 Series

INTRODUCTION

Pressure / Vacuum relief valves are used on liquid storage tanks and other process vessels or systems to prevent structural damage due to excess internal vacuum. Storage tanks are pressurized when liquid is pumped in, compressing the existing vapor or when rising temperatures cause increased evaporation or expansion of existing vapor.Conversely, a vacuum condition may be created when pumping out or due to falling temperature. To prevent tank damage, vapor must be allowed into or out of the tank at specified vacuum condition. The volume rate of venting depends upon the tank size, volatility of the tank contents, the pumping rates and the temperature.

MODEL NAME : NK-BV15 SERIES

DESIGN AND FUNCTION

|

Model No. |

Type | Material |

Setting Pressure Range |

|

NK-BV15W |

Weight Loaded release to ATM | Aluminum, Carbon Steel, Stainless Steel |

22 ~ 700 mmH2O |

|

NK-BV15S |

Spring Loaded to ATM | Aluminum, Carbon Steel, Stainless Steel |

Above 700 mmH2O |

Note) Other specification to be consult by factory.

Tank protection equipment typically includes an operating valve, which is designed to provide pressure/vacuum relief under normal pump in/out and thermal breathing conditions.

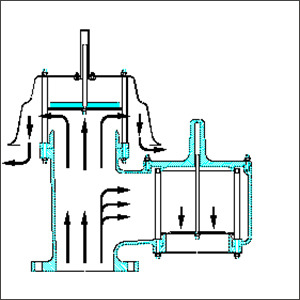

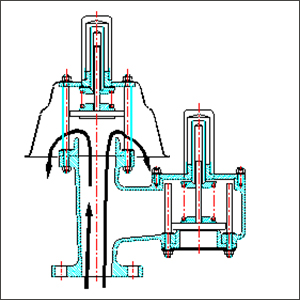

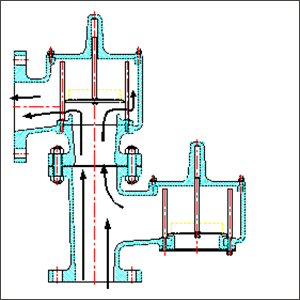

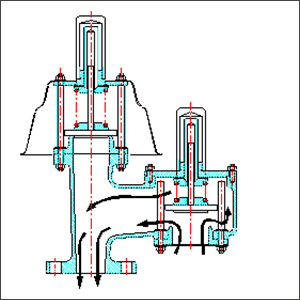

Pressure Relief

As the pressure in the storage tank increases, the vacuum pallet is held shut.When the set pressure is reached, the pressure pallet lifts and relieves to atmosphere (or to a header if it a pipe away valve).

MODEL NAME : NK-BV12W

MODEL NAME : NK-BV12S

MODEL NAME : NK-BV15W

MODEL NAME : NK-BV15S

Vacuum Relief

As a vacuum is drawn in the storage tank (for example, when fluid is being pumped out), the pressure pallet is held shut by atmospheric pressure. When the vacuum setting is reached, the pallet lifts and air is drawn in the storage tank from the atmosphere.

Model NK-BV12, NK-BV15 is designed to protect the low-pressure tank from damage created by overpressure or excessive vacuum.

Model NK-BV12, NK-BV15 has a self draining house and drip ring to protect the seating surfaces from condensation and freezing. The pressure and vacuum relief valve is installed on the storage tank roof. Also can this valve be mounted in conjunction with a NK-FA21 flame arrester to protect against ignition of flammable vapors from external sources as well as to provide pressure vacuum relief. Model NK-BV15 is used for pressure and vacuum relief where vapors must be piped away.

MODEL NAME : NK-BV12W

MODEL NAME : NK-BV12S

MODEL NAME : NK-BV15W

MODEL NAME : NK-BV15S

INSPECTION AND STORAGE

The vacuum relief valve is carefully packaged to prevent damage or contamination during shipping. Inspect all equipment when it is received: report any damage to the carrier immediately. The valve should be protected during handling and storage. Keep all the ports plugged to prevent intrusion of foreign materials. Before installation, inspect the unit for indications of physical damage or internal contamination. If these are observed, the valve must be disassembled, cleaned and repaired before installation.

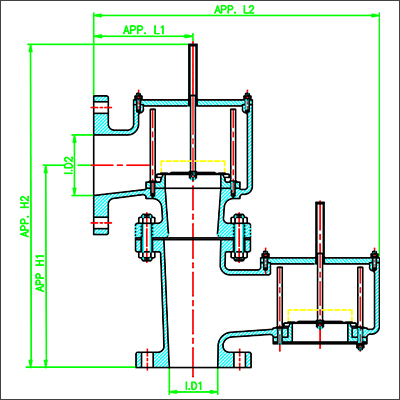

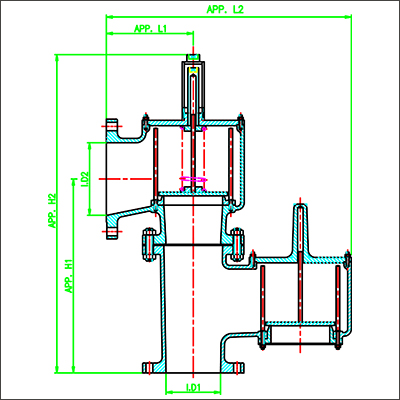

DRAWING AND DIMENSION

| SIZE | I.D1 | I.D2 | H1 | H2 | L1 | L2 |

| 2” x 3” | 50 | 80 | 320 | 490 | 150 | 400 |

| 3” x 4” | 80 | 100 | 360 | 555 | 160 | 472 |

| 4” x 6” | 100 | 150 | 413 | 700 | 217 | 535 |

| 6” x 8” | 150 | 200 | 533 | 842 | 238 | 665 |

| 8” x 10” | 200 | 250 | 602 | 920 | 253 | 785 |

| 10” x 12” | 250 | 300 | 679 | 1037 | 298 | 890 |

| 12” x 14” | 350 | 400 | 758 | 1159 | 330 | 1025 |

UNIT : mm

| SIZE | I.D1 | I.D2 | H1 | H2 | L1 | L2 |

| 2” x 3” | 50 | 80 | 320 | 490 | 150 | 400 |

| 3” x 4” | 80 | 100 | 360 | 555 | 160 | 472 |

| 4” x 6” | 100 | 150 | 405 | 677 | 220 | 535 |

| 6” x 8” | 150 | 200 | 533 | 876 | 238 | 665 |

| 8” x 10” | 200 | 250 | 602 | 950 | 253 | 785 |

| 10” x 12” | 250 | 300 | 679 | 1067 | 290 | 890 |

| 12” x 14” | 300 | 350 | 758 | 1189 | 330 | 1025 |

UNIT : mm