Flame Arrester NK-FA23T

Model NK-FA21T, NK-FA23T is bi-directional type and designed to be installed in “open vent pipes” from storage or processing tanks, bleed lines or other vapor conveying lines. The flame arrester consists of a spiral wound and crimped bank element, is designed for easy maintenance.

After removing tie rod bolts, it can be expanded by using the remaining jackscrews for element exchange. Model NK-FA21T, NK-FA23T is used to prevent propagation of an external flame source through the vent opening and into the tank. It should be installed at distances of more than 20 times length of arrester N.D away from the open end of pipe.

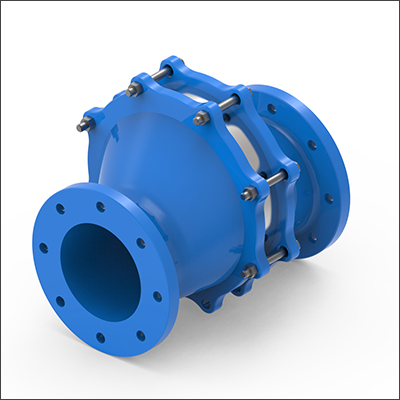

MODEL NAME : NK-FA23T

NK-FA23T PHOTO

NK-FA23T PHOTO

SPECIFICATIONS

| MODEL NAME | NK-FA23T |

| TYPE | IN-LINE FLAME ARRESTER |

| SIZE | 2” THROUGH 12” |

| INSTALLATION | VERTICAL / HORIZONTAL INSTALL |

| CLASSIFICATION | DEFLAGRATION FLAME ARRESTER / BI-DIRECTIONAL |

| NORMAL WORKING PRESSURE | BELOW 10000mmH2O (STANDARD SPECIAFICATION) |

| EXPLOSION GAS GROUP | IIA(standard), IIB/IIC(for special application) |

MATERIALS

| PART NAME | MATERIALS STANDARD | MATERIALS OPTIONAL |

| BODY | C.S / SUS304 / SUS316 / ALUMINUM | Hastelloy, Alloy 20, Monel, Inconel |

| ELEMENT | 316L SS | Hastelloy, Alloy 20, Monel, Inconel |

| HOUSING | C.S / SUS304 / SUS316 / ALUMINUM | Hastelloy, Alloy 20, Monel, Inconel |

| HOOD | 304 SS / 316SS | 316L SS |

| BOLT and NUT | C.S / 304 SS / 316 SS | 316L SS |

FLAME ARRESTER

A flame arrester is a safety device installed on a nozzle on top of a tank when the flash point of the stored product is lower than the possible tank temperature.

A majority of the time, a “vent to atmosphere” pressure / vacuum valve is installed on top of the flame arrester. A flame arrester is also used as in-line safety device where combustible gases are transported through low pressure pipe lines to actual combustion, as in an incinerator or flare or where combustion fumes are vented through piping to atmosphere where lightning can cause a flame. Flame arresters should be designed to stop tank farm fires caused by lightning, sparking, a flame arrester must act as a barrier (stop a flame), a flame holder (contain the flame at the barrier), and dissipate heat in order to prevent auto ignition on the down side of the flame arrester.

Flame Arresters are designed to inhibit flame propagation in gas piping systems and to protect low pressure tanks containing flammable liquids. They protect low flash point liquids from externally caused sources of heat and ignition, providing increased fire protection and safety. The flame arrester consists of two main components, the arrester bases and the flame element housing. The bases serve as the connecting interface to the piping system. The housing accommodates the flame element and is instrumental in stopping the flame passage. The flame element is comprised of small parallel triangular passageways aligned so that an approaching flame front is slowed down and then quenched before it can propagate to the protected side of the device. All NEOTECHKOREA flame elements utilize spiral wound, crimped ribbon constructed of corrosion resistant materials, to insure the best flame quenching performance with minimum pressure drop. A flame arrester should be treated as a safety device and maintained by a knowledgeable repair technician.

STD. CRIMPED BANK ELEMENT STRUCTURE

In order to be an effective flame prevention device, a flame arrester must have a quenching or hydraulic diameter small enough to stop the flame created by the combustible gas. Each combustible gas has a different required hydraulic diameter to be able to stop the flame. In addition to stopping the flame, an arrester must be able to dissipate heat. Flame element mass ensures that hot gases above the auto ignition temperature never reach the downstream side of the flame arrester. With an in-line installation, structural integrity is important to insure safety if a detonation should occur. Proper gasket to insure an oxygen free environment in the event of a detonation is also important. Unless a flame arrester meets or exceeds the above mentioned design criteria, it is not a true flame arrester.

INSPECTION AND INSTALLATION

All NEOTECHKOREA flame arresters are bi-directional and the installation on a tank or piping system depends to a great extent on the design of the system. The Model NK-FA21T is recommended for vertical installation in closed piping systems or venting to atmosphere. (Model NK-FA23T: Horizontal Installation) If a Model NK-FA21T is installed in a horizontal line, it should be equipped with drain ports for removal of condensation from the housing.

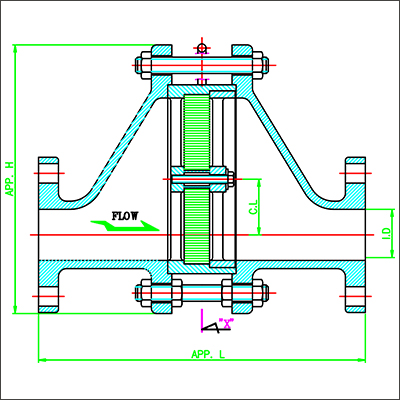

DRAWING AND DIMENSION

| 2” | 3” | 4” | 6” | 8” | 10” | 12” | |

| I.D | 50 | 80 | 100 | 150 | 200 | 250 | 300 |

| H | 223 | 280 | 310 | 400 | 480 | 587 | 680 |

| L | 320 | 330 | 340 | 385 | 470 | 490 | 560 |

UNIT : mm